Phone:

(701)814-6992

Physical address:

6296 Donnelly Plaza

Ratkeville, Bahamas.

Underwater welding is consistently ranked among the world’s most dangerous professions, with a staggering fatality rate of about 15% per year. This alarmingly high death toll underscores the extreme risks these professionals face daily.

It combines the risks of deep-sea diving with the dangers of welding. In this article, we’ll explore why it’s so risky and what challenges underwater welders face.

Underwater welders work in places with very high pressure. As they go deeper underwater, the pressure gets stronger. This pressure can hurt their bodies in many ways. It can affect how blood flows, how their joints work, and even how they breathe. Divers can get something called barotrauma, which causes pain in their ears and sinuses. The gear they use, like diving suits and helmets, must be strong enough to handle this pressure. If the gear fails, it can be very dangerous.

A study showed that divers working deeper than 30 meters (about 98 feet) are 10 times more likely to get decompression sickness than those working in shallower water. This is why underwater welders need lots of training. They learn about how the body works underwater, how to come back up safely, and what to do in emergencies. Being an underwater welder means being tough and knowing a lot about diving and welding.

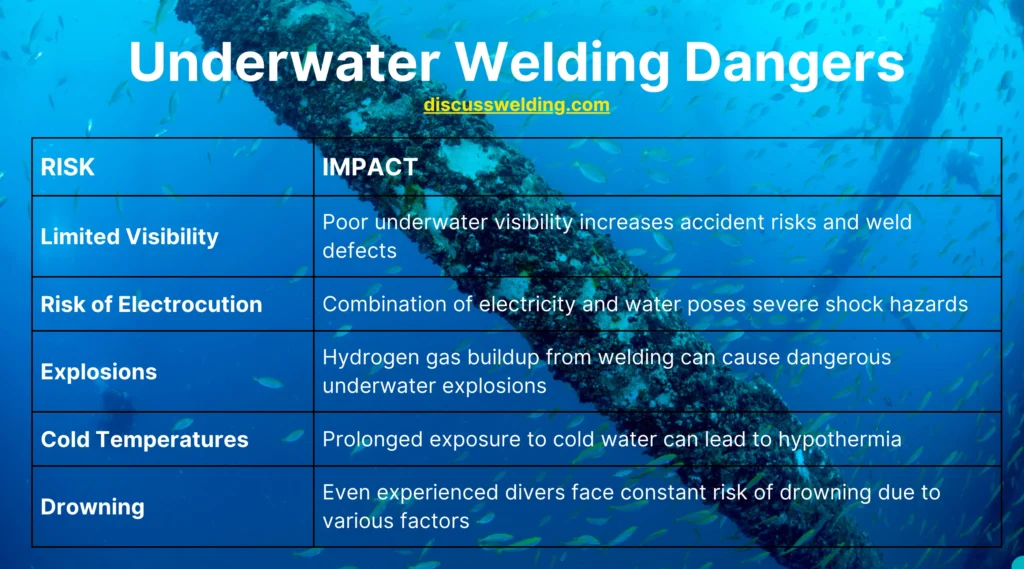

Underwater welders often work in water where they can’t see well. The water is often cloudy because of dirt, tiny bits of plants, and other stuff floating around. Sometimes, they can barely see anything at all. This makes their job really hard. When welders can’t see, they have to rely on touch and memory to find where they need to weld. Not being able to see well can lead to welds that aren’t perfect, which can be dangerous for the things they’re working on.

To help with this problem, welders use special lights and masks made for working underwater. But even with these tools, they still need to be really good at working by feel. The poor visibility doesn’t just make the work harder, it also makes accidents more likely. Welders might not see dangers around them. That’s why they need lots of practice working in water where they can’t see well. It helps them stay safe and do a good job.

Underwater welding is extra dangerous because it mixes water and electricity. When welding, the welder creates an electric circuit between their tool and the metal they’re working on. Water can easily conduct electricity, which makes getting shocked a big risk. Even a small shock in water can be deadly. This is because our bodies conduct electricity better when we’re wet. The Occupational Safety and Health Administration (OSHA) warns that even low voltage shocks can kill in water. To stay safe, welders need to use tools with really good insulation.

They also need to keep a safe distance from any parts that have electricity running through them. Welders get a lot of training on how to avoid electric shocks. They learn to check their gear carefully before each dive to make sure nothing is broken or worn out. Even with all these safety steps, the risk is always there. The underwater environment can be unpredictable, so welders have to stay super focused on safety all the time they’re working.

Underwater welding can cause explosions, which is another big danger. When welders work, they break down water into its parts. One of these parts is hydrogen gas. This gas can build up in small spaces near where the welding is happening. If the welding spark or heat touches this gas, it can explode. To avoid this, welders have to be very careful about how they weld. They need to keep the right distance between their tool and the metal. They also use special welding rods that make less hydrogen.

Understanding how these explosions can happen is really important for staying safe. An explosion can hurt the welder and damage their equipment. It can also make the welder confused or dizzy, which could lead to other accidents. To prevent explosions, welders need good training. They learn special techniques and follow strict safety rules while they work.

Underwater welders often work in very cold water. This cold can be dangerous if they stay in it too long. The biggest risk is hypothermia, which happens when the body gets too cold. Water takes heat away from the body much faster than air does. To stay warm, welders wear thick wetsuits and sometimes even use heated underwear. But even with this gear, they can’t stay in cold water for too long. The cold doesn’t just make welders uncomfortable. It can affect how well they think and move. This makes their job harder and more dangerous.

Welders need to know the signs of hypothermia, like shivering, confusion, and feeling very tired. They also need to know when to get out of the water to warm up. Teams working on underwater welding jobs often rotate divers to make sure no one gets too cold. Staying warm is a big part of staying safe for underwater welders.

Even though underwater welders are experienced divers, drowning is always a risk. The underwater world can be unpredictable. Strong currents can suddenly appear. Equipment can get tangled on things underwater. Emergencies can happen quickly. To stay safe, welders need lots of training in how to handle problems underwater. They learn how to control their floating, how to stay calm in scary situations, and how to make quick decisions.

Panicking underwater is very dangerous and can lead to drowning. Welders also use special diving gear that helps them breathe underwater. They need to check this gear carefully before every dive. Working with a team is important too. Usually, there are other divers nearby who can help if something goes wrong. Even with all this training and teamwork, welders always need to be alert and ready to deal with dangers that could lead to drowning.

Decompression sickness, often called “the bends,” is a serious risk for underwater welders. It happens when a diver comes up to the surface too quickly. When divers are underwater, the high pressure causes nitrogen to build up in their blood and tissues. If they come up too fast, this nitrogen forms bubbles in their body, kind of like opening a soda can too quickly. These bubbles can cause a lot of problems. Divers might feel pain in their joints, get dizzy, or even become paralyzed. In the worst cases, it can be fatal.

To avoid this, welders follow strict rules about how to come back to the surface. They rise slowly and often stop at certain depths for a while. This lets the nitrogen leave their body safely. Welders use special tables or computers to plan their ascent. They also need to be careful not to push their limits and stay underwater for too long.

For underwater welders, having their equipment fail can be life-threatening. They rely on a lot of gear to keep them safe and let them do their job. This includes things like air tanks, regulators (which help them breathe underwater), wetsuits, and welding tools. If any of this equipment stops working properly, it can put the welder in serious danger. For example, if a regulator fails, the welder might not be able to breathe. If a wetsuit tears, cold water can get in and cause hypothermia.

To prevent these problems, welders check their equipment carefully before every dive. They also learn how to handle equipment failures underwater. Many divers carry backup equipment for critical items. Regular maintenance of all gear is super important. Welders also train in emergency procedures, like how to share air with a buddy or how to quickly return to the surface if something goes wrong. Being prepared for equipment problems is a key part of staying safe.

Underwater welding is a critical yet hazardous profession that demands extensive training, experience, and constant vigilance. Despite these risks, their work is essential for maintaining underwater structures, pipelines, and vessels. As technology advances, new safety measures and equipment continue to improve working conditions.

However, the inherent dangers of combining diving and welding ensure that this profession remains one of the most challenging and respected in the industrial world. Proper training, strict adherence to safety protocols, and ongoing research are crucial to protecting these skilled professionals.